Gluematic GM 6000 3K – The King of The Gluing Systems

Pro-Hydro patented GM 6000 Temperature Compensated open time control system

Gluematic GM 6000 3K is a gluing system developed and patented by Pro-Hydro. Pro-Hydro Gluematic has superior features compared to traditional 2 K systems:

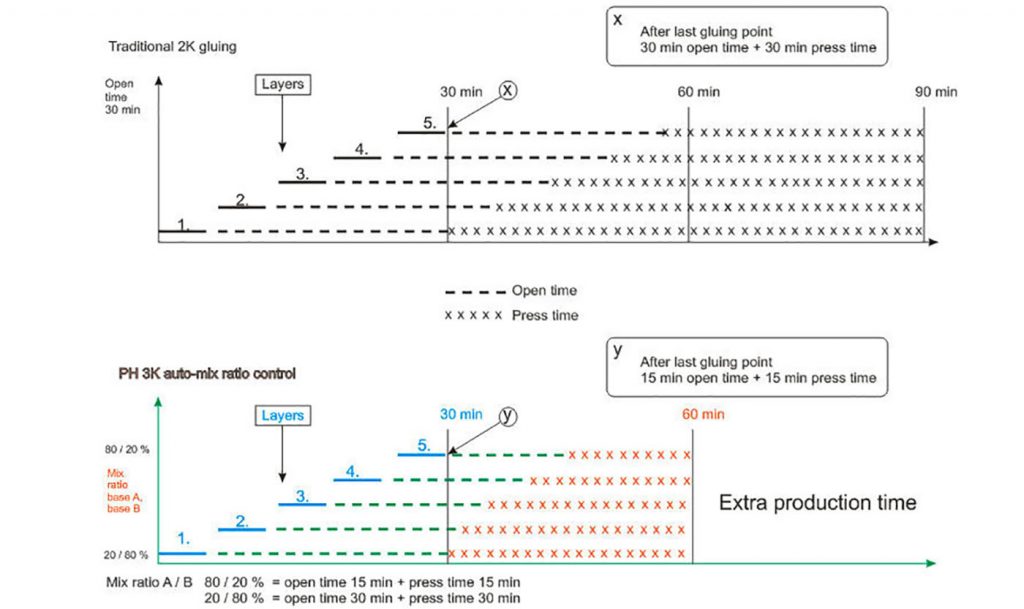

- Pressing time even 50% shorter

- 100 % mixing ratio control

- Non-pulsing material flow

- No user or system based errors

- Temperature of the factory premises is automatically considered when setting the open time

- Temperature differences of summer and wintertime are compensated

THE MOST EFFECTIVE AND MOST RELIABLE!

Major benefits comparing 3K to 2K systems

- Possible to choose the most suitable open time for the element.

- The pressing time can be reduced by even 50% by setting the optimized open time.

- Open time can be shortened during the element layering time, for example from 60 minutes to only 30 minutes.

- Temperature of the factory premises is automatically considered when setting the open time.

- Temperature differences of summer and wintertime are compensated

- The glue flow can be optimized with extremely accurate material flow control.

- No failures in gluing due to mixture ratio and flow accuracy.

- Reliability of the system is extremely high – non-stop production.

- Maintenance can be scheduled on annual shut downs

- Monitoring system helps to eliminate user errors: 100 % control: flow, mixture, open time, pressing time, user’s name for each layer, air temperature etc….

- The calibration made on installation is the only one ever needed.

- Mixture ratio and flow checks are unneccessary (always better than +/- o,5%).

- 1-3 year maintenance interval depending on the usage.

- Annual maintenance takes about 4 hours and two men.

- Mixer and glue spreader cooling reduces the need for cleaning significantly.

Do You Have An Upcoming Project?

If you have an upcoming project, why not take advantage of expert services to

help you achieve the complete success of your project.